TEL:010-82133252

FAX:010-82133282

E-mail:src@sr-business.com

Shanghai office:

TEL:021-64700358

FAX:021-64706540

Guangdong office:

TEL:020-84016200

FAX:020-84016006

Consistent quality is materialized in a bid to achieve higher practicability.

Meeting every performance requirement for antimicrobial concrete.

![]()

| Gmax (mm) | W/C (%) | S/a (%) | Unit quantity (Kg/m3) | |||

|---|---|---|---|---|---|---|

| W | C | S | G | |||

| 15 | 42.5 | 47.0 | 178 | 419 | 823 | 958 |

| Slump (cm) | Air content (%) | Concrete performance | Compression strength | ||

|---|---|---|---|---|---|

| (N/mm2) | (Kgf/cm2) | ||||

| Without Zeomighty | 4.5 | 1.5 | Good | 47.3 | 483 |

| With Zeomighty | 4.5 | 1.7 | Good | 48.7 | 497 |

Note: Compression strength was measured with concrete cured at air dry after steam curing.

In view of its dispersibility to concrete in casting, Zeomighty is made with materials falling in the same specific-gravity bracket with cement and aggregates. Furthermore, since its particle size distribution is controlled to match with those of cement and admixtures, an ordinary plant can mix it into mortar or concrete and attain good dispersion.

In mixing it into concrete, please use a mixer conforming to the requirements of the JIS mixer performance test.

Antimicrobial agent distribution was examined by varying a mixing time in the range from 30 to 90 seconds with a pan-type mixer and a forced, dual-axis mixer. Sufficiently good dispersion was obtained with both mixers for 60 seconds or a longer mixing time.

| Mixer | Mixing time | Average | Standard deviation: σ | Number of samples: n |

|---|---|---|---|---|

| Pan type mixer | 30 seconds | 1.25 | 0.29 | 4 |

| 60 seconds | 1.02 | 0.04 | 4 | |

| 90 seconds | 1.03 | 0.04 | 4 | |

| Forced, dual axis mixer | 30 seconds | 1.03 | 0.03 | 6 |

| 60 seconds | 1.02 | 0.02 | 6 | |

| 90 seconds | 1.01 | 0.01 | 6 |

Values represent the percentage of Zeomighty to cement in weight.

Samples were taken from the core areas of typical products representing centrifugal casting, vibration casting and slush casting to examine antimicrobial agent distribution.

The state of antimicrobial agent distribution in Hume pipes is summarized in two tables. Both cases showed acceptable antimicrobial agent distribution.

It was surmised that slightly lower values measured near the outer surface was attributable to uneven coarse aggregate distribution. With the measurement of antimicrobial agent distribution in products with an electron probe micro-analyzer, the uniformity of antimicrobial agent distribution was ascertained.

| Casting method | Product name | Average | Standard deviation: σ | Number of samples: n |

|---|---|---|---|---|

| Centrifugal casting | Hume pipe 1 | 1.14 | 0.06 | 6 |

| Hume pipe 2 | 1.10 | 0.08 | 6 | |

| Vibration casting | Manhole | 1.24 | 0.05 | 6 |

| Box culvert 1 | 1.28 | 0.05 | 6 | |

| Box culvert 2 | 1.17 | 0.09 | 6 | |

| Slush casting | Tile joint repair | 1.01 | 0.02 | 6 |

Values represent the percentage of Zeomighty to cement in weight.

| Depth from the inner surface | Average | Standard deviation: σ | Number of samples: n |

|---|---|---|---|

| 0?3mm | 1.12 | 0.02 | 3 |

| 3?6mm | 1.11 | 0.08 | 3 |

| 6?9mm | 1.05 | 0.01 | 3 |

| 20?23mm | 0.88 | 0.04 | 3 |

| 30?33mm | 0.86 | 0.05 | 3 |

| 47?50mm | 0.82 | 0.05 | 3 |

(For use as a buried pipe subject to compressive pressure, type 1, nominal diameter 600)

Values represent the percentage of Zeomighty to cement in weight.

Shiny spots indicate the presence of Zeomighty's active ingredients. The image shows their distribution over the entire area.

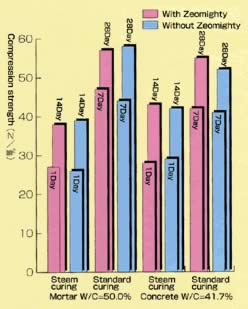

The compression strength of mortar and concrete with Zeomighty added at 1% was measured for each curing and age condition.

No significant change in the compression strength was observed from mortar or concrete without Zeomighty, so you can use it confidently.